Key Properties and Advantages of Synthetic Fibres

Clothes are one of the main requirements of human beings. They are mostly made of fabrics and these fabrics are made of fibres. There are natural and synthetic fibres.

Artificial fibres which are prepared from raw materials such as petrochemicals are called synthetic fibres. They are mainly synthesised in chemical laboratories. They are the result of extensive research carried out by scientists to replace them with animal and plant-based fibres.

Synthetic Fibres

What are Synthetic Fibres?

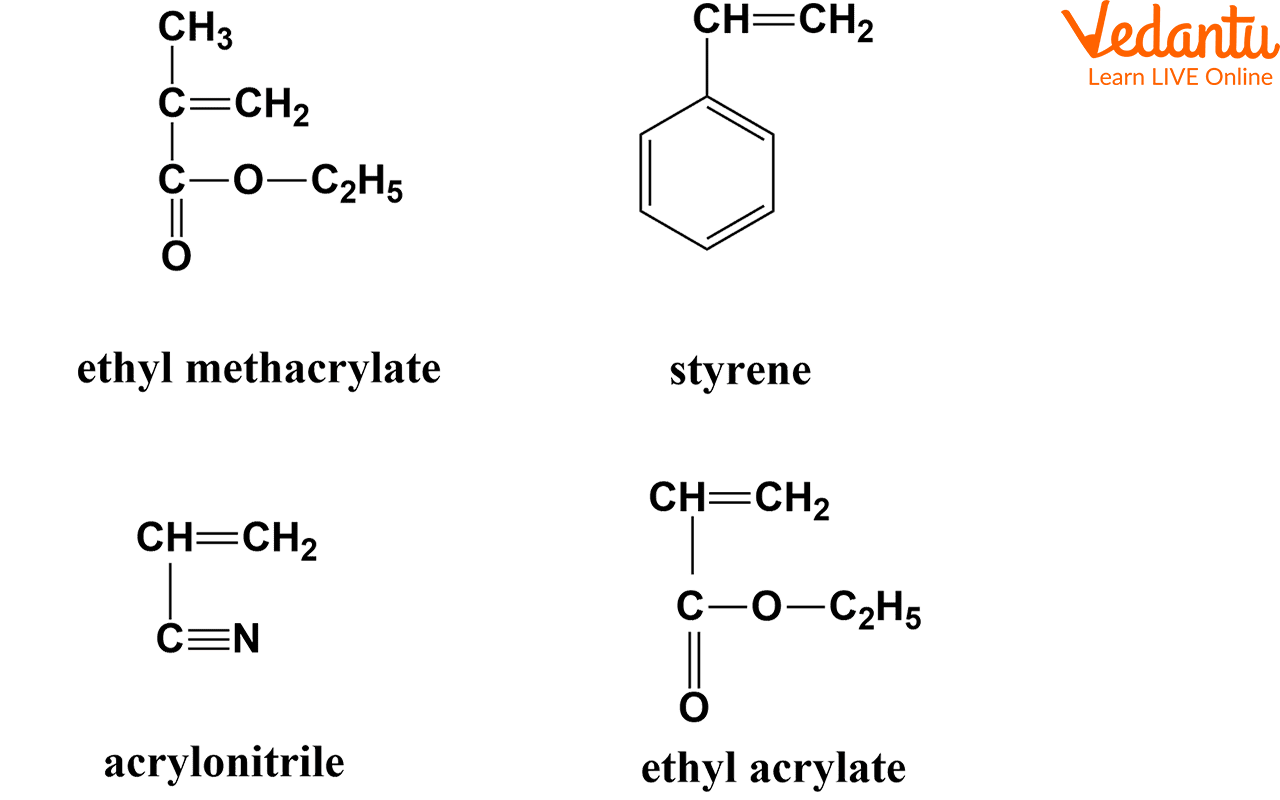

Artificial fibres or synthetic fibres are mainly produced from petrochemicals. They are polymers that consist of small units or monomers. These monomers are synthesised from petrochemicals. The carbon atom of the monomers is linked with another monomer and finally, a polymer is obtained.

The word polymer has its origin in the Greek language. Poly means many and mer means units. Thus these fibres are polymers that are made up of small units or monomers.

Monomer Structures of Different Polymers

Examples of Synthetic Fibres

The textile industry is hugely dependent upon synthetic fibres. They have various properties and they are economical. That is why they have gained huge popularity and have been useful for various purposes. Rayon, Nylon, and Polyester are three of the most important synthetic fibres.

Nylon

This was the first fully synthetic fibre prepared.

It is a polyamide.

They were synthesised using coal, air, and water.

There are various types of nylon. (Nylon-6,6, Nylon-6, etc)

These have various properties which make them popular.

They are strong, elastic, and lustrous.

It dries quickly.

They are used for various articles like socks, ropes, and tents.

Since they are strong, they are used in parachutes also.

Nylon Rope

Rayon

This is obtained from wood pulp. So it is not fully synthetic.

This is also known as artificial silk.

It has its origin in the French word rayonne.

This was prepared to replace costly natural silk.

These can be dyed with different colours.

They are also mixed with different fibres like cotton and wool to produce bedsheets and carpets.

They are soft, absorbent, and comfortable.

It is shrunk-resistant and dries easily.

Due to their cost-effectiveness and comfortability, they are quite popular.

Raylon

Polyester

This fibre is prepared from coal, water, and petroleum.

The chemical called ester is the monomer.

The polyester is easy to wash, economical, and wrinkle-free.

It is quite popular and used to produce various dress materials.

It can retain its shape and is crisp.

They are insulators.

They are stain-resistant.

They are useful in the manufacturing of ropes, nets, jackets, dresses, and raincoats.

Polyester Fabric

Uses of Synthetic Fibres

There are various uses of synthetic fibres in our day-to-day life Each one has its unique properties and various applications. They are mainly used in sectors like aerospace, apparel, construction, chemical industries, marine, medical, and welding. Here we can discuss various applications of the different synthetic fibres.

Nylon

Clothing: Used in the manufacture of swimwear, sportswear, raincoats, shirts, garments, etc

Industries: Used in the manufacturing of conveyor belts, ropes, parachutes, net, threads, and tents

Manufacturing of plastics.

Rayon

Clothing

Hygiene: Used in tampons and sanitary pads

Food packaging: Used as a substitute for cellophane.

Used to manufacture carpets, bedsheets, home decors, curtains, and table cloths.

Polyester

Clothing: Used to produce shirts, pants, trousers, jackets, hats, and sarees.

Manufacturing of home decor items, bed sheets, curtains, pillowcases, and blankets.

Used in the manufacturing of upholsteries, conveyor belts, safety belts in automobiles, and mouse pads.

They are also used in the manufacturing of dielectric films in capacitors, film insulation in insulation tapes, and used in LCDs (Liquid crystalline display).

They are also used in the manufacturing of bottles.

Advantages and Disadvantages of Synthetic Fibres

Advantages

They are wrinkle-resistant.

They are easy to wash and easy to use.

They are durable.

They are elastic and strong.

They are cost-effective.

They are lightweight and transportation is easy.

They are good absorbents and will blend well with other fibres.

They are more colourfast than natural fibres.

They are resistant to heat, water, moth, and bacteria.

Disadvantages

They are flammable.

They are repelling and it’s not comfortable to wear during hot summers.

They can be carcinogenic.

They can be toxic to the skin.

They are not environment-friendly.

They can generate waste.

Important Questions

1. Why is it not advisable to burn synthetic fibres?

Ans: When they are burnt, large amounts of harmful gases are evolved and result in air pollution. Also, since they are inflammable they melt easily. They are synthesised using chemicals. Since they are chemically synthesised they produce harmful chemicals and they are not biodegradable. So these will cause problems for our mother nature.

2. What is the importance of synthetic fibres in our day-to-day life?

Ans: They have high strength and flexibility, so they can be used for making ropes, parachutes, and other safety equipment. They are shrink-resistant, economical, lightweight, and can be easily dyed. So they are suitable for clothing, home decor, and curtains. Also, they have insulating properties and they are used in electrical appliances. That is why these are important in our day-to-day life.

Conclusion

Synthetic fibres are artificial fibres that have huge popularity and are very useful in our daily life. They have various properties and due to this, they have large-scale applications. They have both advantages and disadvantages. Due to their wide range of applications, they are used extensively, but we also have to keep an eye on their growing environmental impact. We have to make them more sustainable and environmentally friendly so that they can be used more efficiently.

FAQs on Synthetic Fibres: Complete Guide for Students

1. What are synthetic fibres?

Synthetic fibres are man-made fibres created through chemical processes, primarily using raw materials derived from petrochemicals. Unlike natural fibres obtained from plants or animals, these are artificially produced. They are essentially long chains of small chemical units joined together, a structure known as a polymer. These fibres are then spun into yarn and woven into fabric for various uses.

2. What are the main types of synthetic fibres with examples?

The main types of synthetic fibres commonly discussed in the CBSE syllabus include:

- Rayon: Often called 'artificial silk', it is made from the chemical treatment of natural wood pulp. It is soft, absorbent, and can be dyed in many colours.

- Nylon: The first fully synthetic fibre, made from coal, water, and air. It is known for its exceptional strength, elasticity, and light weight.

- Polyester: A very popular synthetic fibre that is strong, wrinkle-resistant, and dries quickly. Terylene is a well-known example of a polyester fibre.

- Acrylic: Known as 'artificial wool', it is a lightweight, soft, and warm synthetic fibre that is resistant to shrinking and wrinkles. It is often used for sweaters and shawls.

3. Why is nylon considered the first 'truly' synthetic fibre, unlike rayon?

Nylon is considered the first truly synthetic fibre because it was manufactured entirely from non-natural chemical components (coal, water, and air) without using any natural raw materials from plants or animals. In contrast, rayon, while man-made, is produced using a natural raw material—wood pulp (cellulose)—which undergoes chemical treatment. Therefore, rayon is often classified as a semi-synthetic fibre, whereas nylon is fully synthetic.

4. How are synthetic fibres generally manufactured?

Synthetic fibres are manufactured through a chemical process called polymerisation. In this process, many small, individual chemical molecules called monomers are chemically bonded together to form very long chains. These long chains are called polymers. The resulting polymer is then melted or dissolved and forced through a spinneret—a device with fine holes—to form continuous threads, which solidify into fibres.

5. Why are synthetic fibres often preferred over natural fibres like cotton for making certain types of clothing?

Synthetic fibres are often preferred over natural fibres for specific applications due to their unique properties. Key advantages include:

- Durability: They are generally stronger and last longer than natural fibres.

- Wrinkle Resistance: Fabrics made from synthetic fibres do not wrinkle easily and maintain their crisp appearance.

- Quick Drying: They absorb very little water, which makes them ideal for sportswear and rainwear as they dry quickly.

- Cost-Effectiveness: They are typically less expensive to produce than natural fibres like silk or wool.

6. What are the main disadvantages of wearing clothes made from synthetic fibres?

Despite their benefits, synthetic fibres have some significant disadvantages, particularly concerning comfort and safety. Firstly, they are not good at absorbing sweat, which can make them uncomfortable to wear in hot and humid weather. Secondly, and more critically, synthetic fibres melt upon heating. This is a major safety hazard, as they can melt and stick to the skin if they catch fire, making them unsuitable for wearing in kitchens or near open flames.

7. How do the properties of polyester make it suitable for a wide range of applications?

Polyester's unique combination of properties makes it extremely versatile. It is exceptionally strong and durable, resistant to stretching and shrinking. A key feature is its excellent wrinkle resistance, which means clothes made from it remain crisp and require minimal ironing. It is also hydrophobic (repels water), allowing it to dry very quickly. These characteristics make it ideal for apparel like shirts and trousers, home furnishings like curtains and bedsheets, and even for industrial uses like ropes and sails.