How Is PVC Plastic Used in Daily Life?

PVC is the abbreviation for Polyvinyl Chloride, and it is one of the most used terms in the manufacturing industry. PVC, or polyvinyl chloride, is a special type of plastic used by various industries. Interestingly, it is the world’s third-most produced synthetic polymer of plastic after polyethylene and polypropylene.

This type of plastic is manufactured in bulk quantities for various purposes. They are highly used in our daily lives. PVC products are even appreciated by many for their cheaper rate. Further in this article, we will discuss the uses of PVC plastic, PVC products, PVC uses and properties, and the application of PVC.

What is PVC?

PVC is a special synthetic polymer and is very flexible. This synthetic polymer was first synthesised way back in 1872 by Eugen Baumann. PVC is manufactured in two basic forms, rigid and flexible. The rigid version of this synthetic polymer is used in the construction of pipes and other building materials. It is also found in various food packets.

On other hand, the flexible version is found in pool liners, rainwear, boots, and many more. The appearance of PVC is white and brittle solid in nature. It is odourless and insoluble in water and ethanol. Interestingly, it is slightly soluble in tetrahydrofuran.

Polyvinyl Chloride

PVC Uses and Properties

Properties of PVC are quite unique. PVC is highly used in various products because of its unique properties. One of the best reasons for such is that PVC is amorphous in nature. This means that this substance can easily be combined with other chemical substances.

PVC Properties

Some properties of PVC are the following

PVC is lightweight, sturdy, and most importantly, abrasion-resistant.

This synthetic polymer is highly resistant to all the additional actions done by any inorganic chemicals.

The durability of PVC is quite good, so one could expect a longer product life.

The use of PVC in any product can help it protect from extreme climatic conditions. It is shock-free and corrosion-free in nature.

The rigid version of PVC offers great tensile strength and is very rigid in nature.

Due to its unique properties, PVC-manufactured objects do not need much maintenance and offer resistance to grease and other oils.

PVC Uses

In today’s world, PVC is mostly used in the manufacturing industry. The use of this product is increasing daily. It is because they require low manufacturing costs and do not need any maintenance. People can use it for a very long period. Here is a list of uses of PVC:-

Electrical devices

Electronics

Automotive sector

Medical industry

Packing

Construction

Applications of PVC

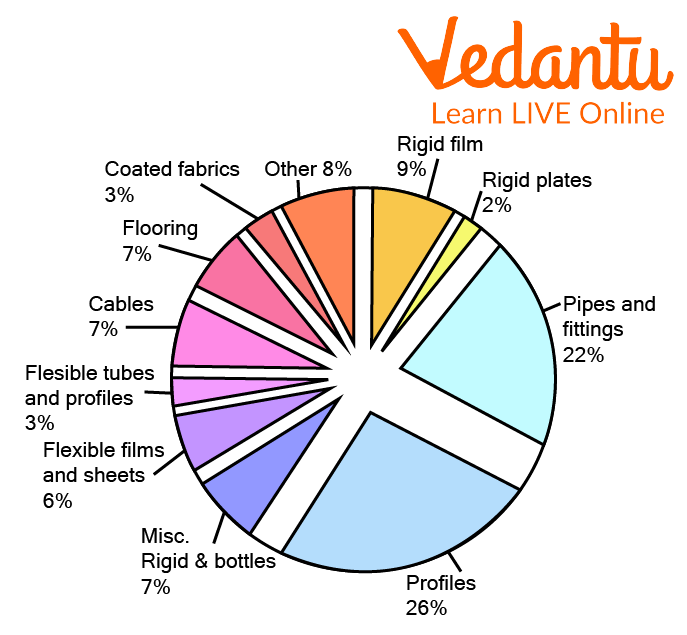

PVC, when mixed with other chemical substances, gives great products for humans. This is one of the reasons why this is highly used in almost every industry. Now, here are some of the uses of PVC plastic:

The plastic version of PVC is highly used in flooring, which is known as PVC-U. On the other hand, the unplasticised version of this is used to make window frames.

The rigid version of PVC plastic is used to make sewage pipelines and other pipe applications. Interestingly, the cost and lifespan of these pipes are way more than any other mixed products on the market.

Both types of PVC are used in construction fields for insulation on electrical wires. They are also used for flooring in hospitals, homes, schools, institutions, and other areas.

Industries like electrical, electronic, and automotive industries use it.

PVCs are also largely used in the garden hose and leather upholstery.

These were some of the applications or uses of PVC plastic around the world and its industries. PVC is widely used to make pipes because they are highly resistant to the attack by kerosene oil. In fact, not only kerosene oil but other dangerous acids and gases as well.

PVC Application

PVC Products

Other than in pipes PVC plastic is used or seen in everyday products. The biggest manufacturer of PVC plastic is Shintech in the United States. This manufacturing company plays a major role in the distribution of PVC around the world. Here are some PVC products: -

PVC insulated cables

PVC flexible cables

PVC power cables

PVC-coated barbed wire

Steel wire

PVC cards

Sleeves

Wall panel

Pipe moulds

Foam boards

These are some of the everyday products that PVC is used to manufacture. In fact, these products will have a longer lifespan than any other products.

PVC Pipes

Summary

PVC is a very special chemical product that was ever established in the human world. The use of this special plastic has saved a lot of money for humans and businesses around the world. Moreover, now we know the uses of PVC plastic, PVC products, what is PVC, and PVC uses and properties. We also know the reason behind the wide usage of PVC in making pipes because it was discussed in the above article.

FAQs on Uses of PVC Plastic: Key Applications and Examples

1. What is PVC plastic, and what are its most common uses in our daily lives?

PVC stands for Polyvinyl Chloride, a versatile and durable type of synthetic plastic polymer. Due to its unique properties, it is one of the most widely used plastics. Some common uses include:

Construction: Water and drainage pipes, window frames, and flooring.

Household Items: Shower curtains, raincoats, and bottles for non-food items.

Electrical Applications: Insulation for electrical wires and cables.

Healthcare: Blood bags and medical tubing.

2. What are the main types of PVC plastic?

There are two primary types of PVC, each with different properties and uses:

Rigid PVC (uPVC): This type is strong, hard, and unplasticized. It is known for its durability and is used for making pipes, window and door frames, and siding for buildings.

Flexible PVC: This type has plasticizers added to it, making it softer and more flexible. It is used for things like electrical cable insulation, inflatable products, flooring, and imitation leather.

3. What key properties make PVC such a useful material?

PVC is highly valued for several important properties that make it suitable for a wide range of applications. Key properties include:

Durability: It is resistant to weathering, chemicals, and corrosion, making it long-lasting.

Water Resistance: PVC does not absorb water, which is why it is ideal for pipes and rainwear.

Electrical Insulation: It is a poor conductor of electricity, making it an excellent and safe material for insulating electrical wires.

Fire Resistance: PVC is inherently flame retardant due to its chlorine content.

4. Why is PVC so commonly used for electrical wires and cables?

PVC is a top choice for insulating electrical wires primarily because it is an excellent electrical insulator. This property prevents the flow of electric current outside the wire, protecting people from electric shock and preventing short circuits. Additionally, its flexible form is tough, durable, and resistant to abrasion, ensuring the wires are well-protected.

5. How is PVC different from other common plastics like PET and Polythene?

While all are plastics, they have different chemical structures and uses. PVC is known for its rigidity and durability, making it suitable for construction materials like pipes. PET (Polyethylene terephthalate) is clear and strong, mainly used for making beverage bottles. Polythene (or Polyethylene) is very flexible and widely used for making plastic bags, films, and containers.

6. What are the environmental concerns associated with using PVC plastic?

Despite its usefulness, PVC has significant environmental drawbacks. Firstly, it is not biodegradable, contributing to plastic pollution in landfills and oceans. Secondly, the production and disposal of PVC can be harmful. When burned, it can release toxic chemicals like dioxins and hydrogen chloride. Recycling PVC is also more complex compared to other plastics like PET.

7. Why is PVC considered a highly versatile material?

PVC's versatility comes from its unique ability to be modified. By adding chemical additives called plasticizers, its properties can be changed dramatically. Without plasticizers, it is hard and rigid (uPVC), perfect for pipes. With plasticizers, it becomes soft and flexible, suitable for clothing or cable insulation. This ability to exist in two different forms—rigid and flexible—allows it to be used in an incredibly wide array of products.