Ball bearings are used in machinery, explain why?

Answer

582.6k+ views

Hint:A ball bearing is a type of rolling element that uses balls to maintain the separation between the bearing races. The purpose of a ball bearing is to reduce friction during motion so that the efficiency of the machine increases.

Step by step solution:

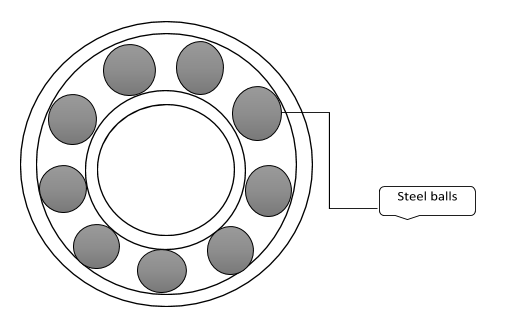

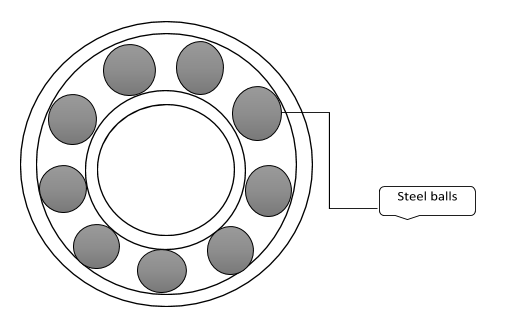

Mechanism of working: The ball bearings consist of two coaxial cylinders between which a suitable number of hard steel balls are arranged as shown in the figure below.

The axle of the vehicle, or machinery, is fitted tightly into the inner cylinder, while the wheel is put in tight contact with the outer cylinder. When the axle rotates clockwise, the steel balls together with the outer cylinder and the wheel rotates anticlockwise. The two cylinders thus have rolling motion relative to each other, instead of sliding over the axle. In this way sliding friction is converted into much smaller rolling friction.

Use in machines:

The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this by using two races to contain the balls and transmit the loads through the balls. As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling, they have a much lower coefficient of friction then if two flat surfaces were sliding against each other.

In general, ball bearings are used in most machinery that involves moving parts such as computer fans, hard disk drives, skateboards, and many more.

Ball bearings are usually used in machines that have a lot of moving work. Ball bearings reduce the friction so that machinery can work smoothly. The sliding friction gets converted to rolling friction which is much less and power dissipation is reduced.

Note: Ball bearings have many advantages but they also have some disadvantages such as they are sensitive to shock loading, they have no muffling of vibrations and are noisy, and their applications may be limited owing to solid races.

Step by step solution:

Mechanism of working: The ball bearings consist of two coaxial cylinders between which a suitable number of hard steel balls are arranged as shown in the figure below.

The axle of the vehicle, or machinery, is fitted tightly into the inner cylinder, while the wheel is put in tight contact with the outer cylinder. When the axle rotates clockwise, the steel balls together with the outer cylinder and the wheel rotates anticlockwise. The two cylinders thus have rolling motion relative to each other, instead of sliding over the axle. In this way sliding friction is converted into much smaller rolling friction.

Use in machines:

The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this by using two races to contain the balls and transmit the loads through the balls. As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling, they have a much lower coefficient of friction then if two flat surfaces were sliding against each other.

In general, ball bearings are used in most machinery that involves moving parts such as computer fans, hard disk drives, skateboards, and many more.

Ball bearings are usually used in machines that have a lot of moving work. Ball bearings reduce the friction so that machinery can work smoothly. The sliding friction gets converted to rolling friction which is much less and power dissipation is reduced.

Note: Ball bearings have many advantages but they also have some disadvantages such as they are sensitive to shock loading, they have no muffling of vibrations and are noisy, and their applications may be limited owing to solid races.

Recently Updated Pages

Master Class 11 Computer Science: Engaging Questions & Answers for Success

Master Class 11 Business Studies: Engaging Questions & Answers for Success

Master Class 11 Economics: Engaging Questions & Answers for Success

Master Class 11 English: Engaging Questions & Answers for Success

Master Class 11 Maths: Engaging Questions & Answers for Success

Master Class 11 Biology: Engaging Questions & Answers for Success

Trending doubts

One Metric ton is equal to kg A 10000 B 1000 C 100 class 11 physics CBSE

There are 720 permutations of the digits 1 2 3 4 5 class 11 maths CBSE

Discuss the various forms of bacteria class 11 biology CBSE

Draw a diagram of a plant cell and label at least eight class 11 biology CBSE

State the laws of reflection of light

Explain zero factorial class 11 maths CBSE