Universal Motor: An Overview

The electric appliances like the washing machines we use in your houses contain a universal motor. A universal motor can run on either DC or single-phase AC power. Also, it is known as a Commutator motor. The speed of the universal motor is over 3500 RPM. DC motors run at higher speeds on a DC supply. However, AC motors run at lower speeds on a DC supply due to the reactance voltage drop present in AC but not in DC.

Construction of Universal Motor

Universal motors are built very similarly to DC machines. A stator is mounted on which field poles are attached. Coils are wound on the field poles. The entire magnetic path is laminated. When operating on AC, lamination is required to minimise eddy currents.

The brushes used in the universal motor have high resistance because there is a commutator with brushes resting on a wound rotary armature that has straight or skewed slots. As a result of the current induced in the coils of the armature, AC commutation is poorer than DC commutation.

Brushes: These are the part of the stator that helps in passing the current to the rotor or moving part of the universal motor. Graphite is commonly used for making brushes.

Commutator: It works like a switch that reverses the direction of current between the rotating part and external circuit during the motion of the universal motor.

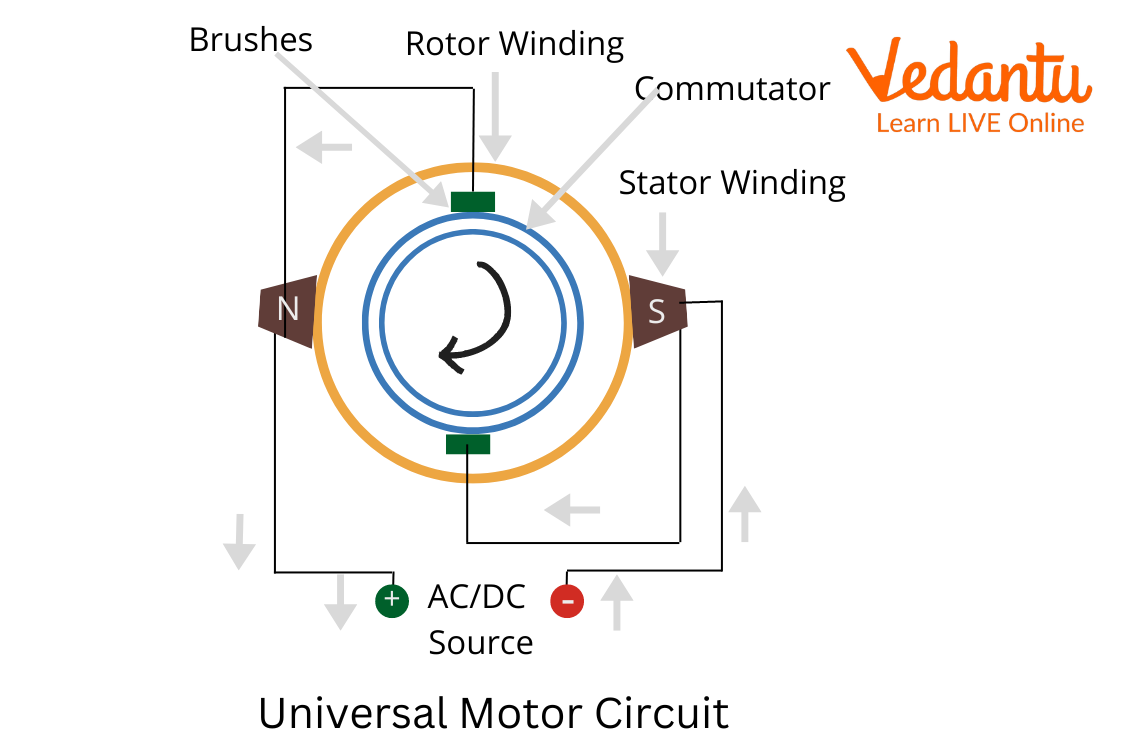

Universal Motor Diagram

A Universal Motor

This is the diagram of a Universal motor where supply is provided by an AC or DC source to the rotor through magnets.

Working of Universal Motors

There are two types of universal motors: DC motors and single-phase AC motors.

When We Provide DC Supply

Field windings produce electromagnetic fields when current flows through them. The same current is flowing through the armature conductors. Mechanical force is experienced by the conductor when it is placed in an electromagnetic field. The rotor starts to rote due to mechanical force or torque. We use Fleming's left-hand rule to find the direction of the force.

When We Provide an AC Supply

The effect of AC supply on the universal motor is that unidirectional torque is produced. Because the armature winding and field winding are connected in series, so they are in the same phase. Hence, AC changes its polarity periodically, and the direction of current for both armature and field winding gets reversed at the same time.

Therefore, the direction of the magnetic field and of the armature current reverse in a way that the direction of force experienced by armature conductors remains the same. It does not depend on whether we use AC or DC supply, a universal motor works on the same principle as that of a DC series motor.

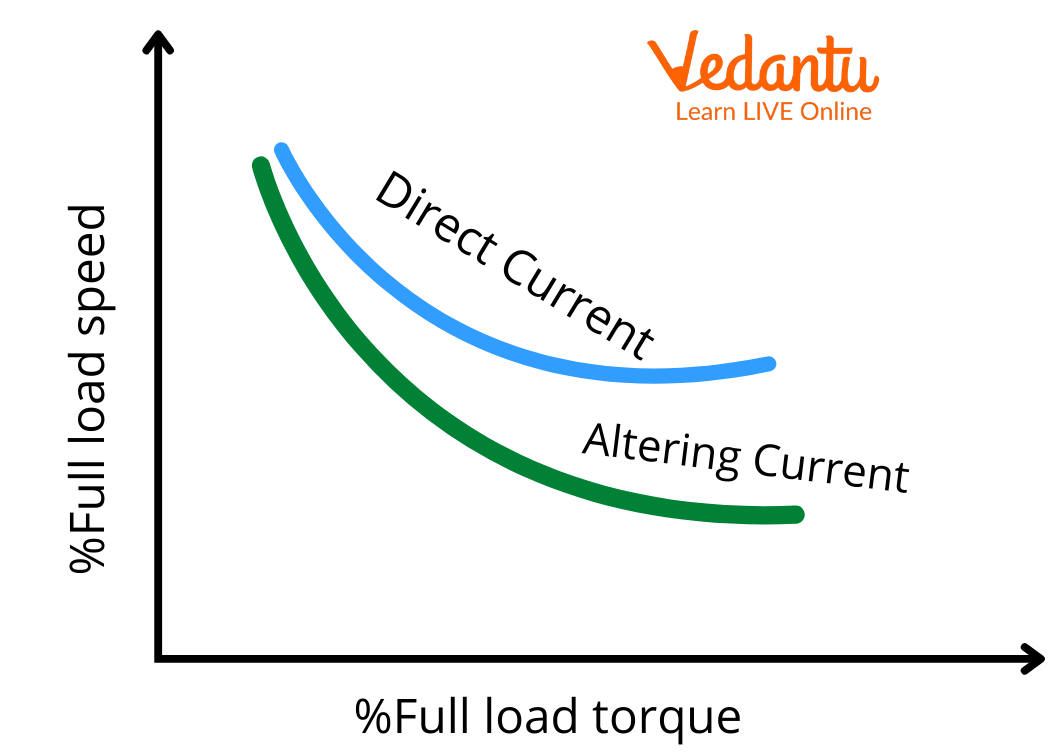

Speed Load Characteristics of Universal Motor

The speed of the universal motor is low at full load and high at no load conditions.

Graph Showing Speed Load Characteristics of Universal Motor

Speed Control of Universal Motor

These motors run at a very high speed to avoid overheating and damage to the motor. We use some methods to reduce the speed of the motor, so they can run at a safe limit.

Method of Controlling the Speed of Universal Motor

The use of rheostat in the line circuit due to this variable voltage appearing across the motor terminals results in reducing the speed of the motor.

Governor controlling method. A governor consists of an assembly of spring-loaded contacts which is mounted on the shaft of a universal motor.

Using a gear mechanism, the gear train is used in this method with different gear sizes according to the requirement to get the desired speed.

Interesting Facts

Due to their cheap running capability, these are used in kitchen and house appliances like a blender, washing machines, electric shavers, hair dryers, vacuum cleaners, etc.

The typical operating speed range for universal motors is between 4000 and 20,000 revolutions per minute (RPM).

Solved Questions

1. What is the principle of the universal motor?

Solution: The armature current and magnetic field directions are reversed, keeping the armature conductors' sense of force in the same direction. Therefore, universal motors operate on the same principle as DC series motors, whether they are powered by an AC or DC supply.

2. What are the two types of the universal motor?

Solution: There are two kinds of universal motors in use: compensated and non-compensated. Typically, focused or conspicuous poles are used to construct the non-compensated motor. The compensated motor, on the other hand, has scattered field windings (main field and compensating winding).

Summary

You are now aware of what a universal motor is and its many varieties. This article discussed this motor as a unique type of electric motor whose power is dependent on both AC and DC. Additionally, this motor has strong starting torque and variable speed characteristics. In addition, we discussed how to regulate the universal motor's speed.

FAQs on Universal Motor

1. What is a universal motor and how does it differ from other types of electric motors in terms of power supply?

A universal motor is a type of electric motor that can operate on either direct current (DC) or single-phase alternating current (AC). Unlike typical AC or DC motors, it is specially designed with series windings and uses a commutator and brushes, allowing it to run efficiently on both power supplies. This dual compatibility gives it unique speed and torque characteristics compared to standard motors.

2. Explain the main components in the construction of a universal motor.

The principal components of a universal motor include:

- Stator: Provides the stationary magnetic field using field windings.

- Armature (Rotor): Rotates and carries current, wound with armature coils.

- Commutator: Reverses current direction in the armature, ensuring unidirectional torque.

- Brushes: Conduct current between stationary and moving parts, typically made of graphite.

- Laminated Core: Reduces energy loss due to eddy currents, especially under AC supply.

3. What are the main applications of universal motors, and why are they chosen for these uses?

Universal motors are commonly used in household and portable appliances such as blenders, mixers, vacuum cleaners, hair dryers, and power tools. They are selected for these applications because of their capability to produce high starting torque, operate at very high speeds, and function efficiently with both AC and DC sources, making them suitable for diverse domestic and industrial uses.

4. Describe the working principle of a universal motor.

A universal motor operates on the principle that a current-carrying conductor placed in a magnetic field experiences a mechanical force. Both the field winding and armature winding are connected in series, so when AC or DC current flows, the direction of both the magnetic field and current reverses simultaneously. This ensures the force direction remains unchanged, producing continuous unidirectional torque regardless of the supply type.

5. How does the speed-load characteristic of a universal motor compare with other motors used in the CBSE curriculum?

Universal motors demonstrate a very high speed at no load and a significant drop in speed as the load increases. This steep speed-load characteristic is distinct from induction and shunt DC motors, where speed variation with load is more gradual. This property makes universal motors suitable for applications where variable speeds are required.

6. What methods are commonly used to control the speed of a universal motor?

The speed of a universal motor can be regulated by:

- Using a rheostat (variable resistor) in series with the motor to adjust the voltage across it.

- A governor mechanism that automatically maintains speed using spring-loaded contacts on the motor shaft.

7. Why are universal motors generally noisier compared to other motors, and what is the main cause of this noise?

Universal motors are noisier because their brushes consistently rub against the slotted armature at high speeds. The rapid mechanical movement and intermittent electrical contacts at the commutator result in significant operational noise, especially as these motors can operate up to 20,000 rpm in some appliances.

8. Compare compensated and non-compensated universal motors, including a key use case for each as per the CBSE Physics syllabus.

Non-compensated universal motors have only main field windings, making them simpler but less stable at high speeds, suitable for small appliances. Compensated universal motors add compensating windings, reducing sparking and improving performance at higher powers. The latter are often used in heavier-duty tools, as outlined in senior secondary Physics.

9. What role do brushes play in the functioning of a universal motor, and why is graphite commonly used in their manufacture?

Brushes conduct electricity between the stationary and moving parts of a universal motor, ensuring current flows into the rotating commutator segments. Graphite is commonly used for brushes because it is lubricating, electrically conductive, and minimizes wear and arcing at high operational speeds.

10. How does the operation of a universal motor relate to Fleming's left-hand rule in Physics?

In a universal motor, Fleming's left-hand rule helps predict the direction of force exerted on the current-carrying armature conductor placed within a magnetic field. The interaction generates a force, causing the rotor to turn and drive mechanical movement, a concept directly explored in the CBSE/NCERT Physics curriculum.

11. What could happen if a universal motor is run continuously at no load, and why is this risky?

Operating a universal motor at no load can cause it to reach dangerously high speeds, potentially leading to overheating, excessive wear, and mechanical failure. This risk is due to the steep speed-load characteristic and minimal resistance to acceleration when no load opposes the motor's output.

12. How does lamination of the magnetic core contribute to efficient operation in universal motors, especially on AC supply?

Laminating the magnetic core in a universal motor reduces energy losses from eddy currents, which are more prominent when running on AC supply. Lamination increases efficiency, lowers heat production, and ensures reliable performance—an important design factor highlighted in CBSE Physics.