What is Vulcanisation and who Invented It?

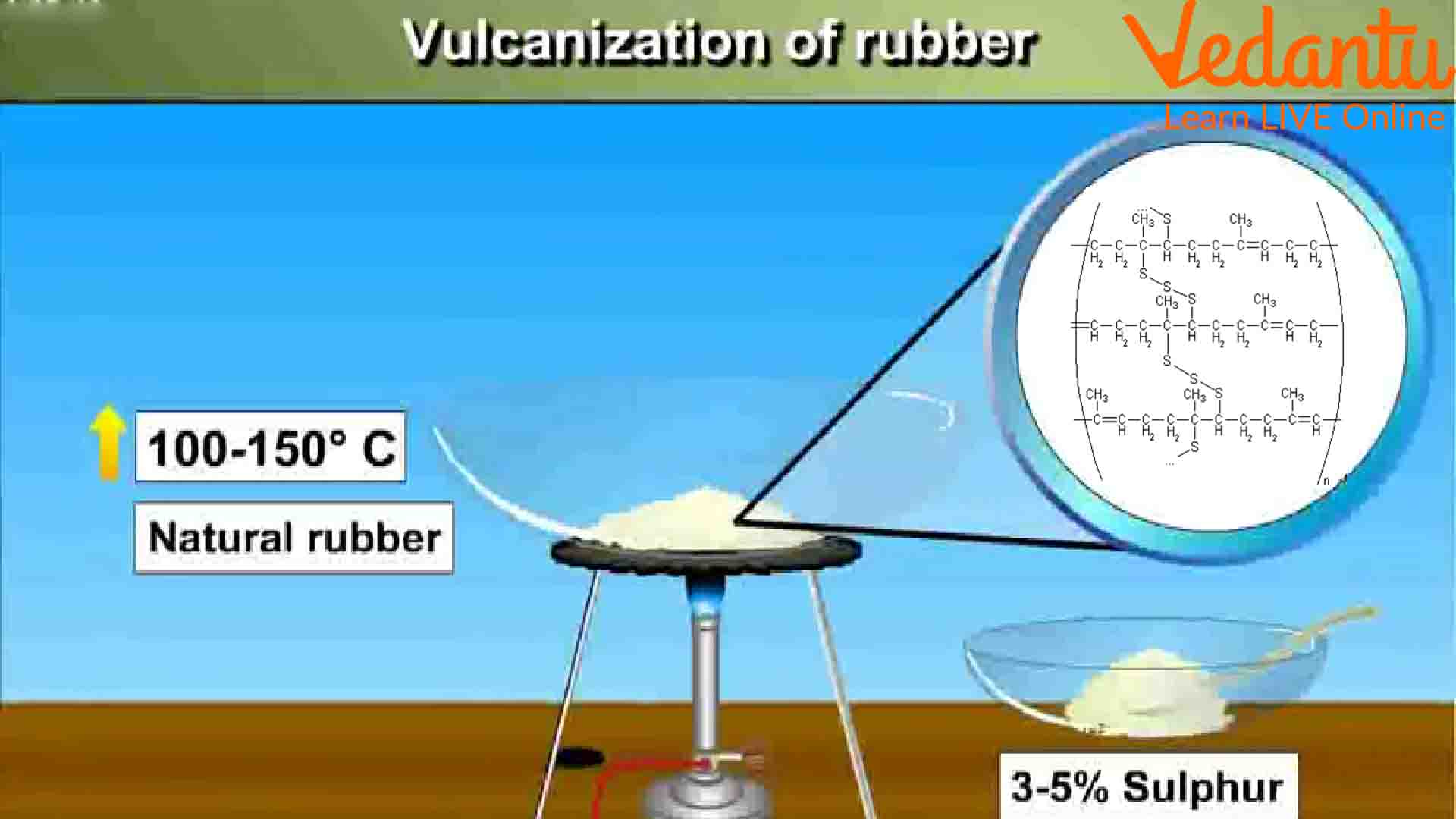

Vulcanisation is a chemical process through which the physical attributes of natural or synthetic rubber are upgraded. During this process, rubber is heated at 140 to 160 degrees Celsius in the presence of sulphur, accelerator and activator. This cross-linking forms a more stable and stronger polymer. The tensile strength of the vulcanised rubber is much higher and it could easily resist getting swelled and eroded. It also remains elastic even during a greater range of temperature and weather conditions.

The entire method of vulcanisation turns the rubber into a smaller size without causing any alteration to its original shape. In this shrunken condition, the rubber hardens, and hence there are lesser chances of deformation. Read ahead to learn more about the properties of natural rubber and why it leads to the invention of the vulcanisation of rubber.

A Brief History of Rubber

There’s no specific person who invented rubber. Christopher Columbus, the legendary Italian explorer and navigator, was the first to witness the Haiti natives playing with a rubber ball in 1495. It is said that the aboriginal cultures of Mesoamerica first used rubber. The fact that rubber was used to make balls for the Mesoamerican ballgame was found in the oldest archaeological proofs, including the Olmec culture of using natural latex from the Hevea Brasiliensis tree. The Olmecs, Aztecs and Mayans still play the ball game using a thousand years old rubber balls.

It takes almost six years before these trees can produce sap and become productive for around twenty-eight years. After that, people used to mix the sap with a juice extracted from the Morning Glory plants to give rubber features like longevity and bounciness. Although rubber originated from South America, about 94 per cent of the entire globe’s natural rubber presently comes from plantations in Southeast Asia. Besides using rubber as a normal eraser, it was used in various other products. But, unfortunately, those products could not withstand extreme temperatures and become brittle during the winters. This was when the process of vulcanisation of rubber was invented, which made the commercial use of rubber possible.

Who Developed Vulcanised Rubber?

Vulcanised rubber was invented by Charles Goodyear in 1843. Goodyear, born on 29th December 1800, was a self-taught American chemist and manufacturing engineer. He started his career as a partner in his father’s hardware business, which couldn’t be continued due to bankruptcy in 1830. So, he then took an interest in developing a method to treat Indian rubber so that it could no longer have adhesiveness and vulnerability to temperature extremities like heat or cold. In this process, he invented a nitric acid treatment and got the contract to produce mailbags using this procedure for the U.S. Government. But sadly enough, it didn’t work in high temperatures.

After failing his first attempt, Goodyear started working with a former employee, Nathaniel M. Hayward, at a rubber factory in Roxbury, Mass, for the next few years. Nathaniel had discovered that rubber, when used with sulphur, was no longer stickier. Goodyear later bought this process from Nathaniel. He dropped some of the Indian rubber mixed with sulphur on a hot stove by a mere chance in 1839 and hence invented the process of vulcanisation for which he was granted his first patent in 1844; only after fighting various contraventions in court. He received two patents in total to make rubber better for commercial purposes.

Rubber Vulcanisation Process

By now, you are aware that vulcanisation is a chemical process by which natural rubber is heated with sulphur to get an improved and upgraded version of rubber that has higher elasticity and tensile strength and is no longer affected by extreme temperatures. Natural or raw rubber is an entanglement of hydrocarbon chains with high molecular weight. Here are four steps to be followed during the rubber vulcanisation process:

Step 1: The first stage is called the scorching stage or the curing induction period. At this stage, the compounds involved in the model have better mobility. The curatives react with each other to get prepared for the cross-linking reaction. This period lets the ingredients mix up safely, keeping them from scorching or premature cooling.

Step 2: The second phase is called the pre-sulphur phase. This is when the rubber molecules have started to chemically cross-link with each other. However, the size, shape and particle size distribution of rubber do not show any changes. The rubber continues to retain its true fluidity and colloidal property.

Step 3: The third phase is known as the sulphur phase or the vulcanisation phase. The ingredients are made to achieve the appropriate cross-linking at this stage. The physical and mechanical characteristics of vulcanised rubber do not reach the highest level simultaneously but are very close to their best value. The temperature and the time taken at this level are called the positive cure time and the normal vulcanisation temperature, respectively.

Step 4: The last phase is called the over-sulphur phase. At this stage, the vulcanised rubber starts entering the sulphur-curing phase. The oxidation and thermal chain-breaking reactions occur throughout the vulcanisation process, but at different stages, these two reactions occupy different statuses. In this last level, these reactions are frequently found to be dominant. This results in a phenomenon in which the rubber's physical and mechanical features decrease.

Uses of Vulcanised Rubber

Today vulcanised rubber is used to manufacture all kinds of products. The best possible known and the most widespread use of vulcanised rubber is vehicle tyres, combined with carbon black to act as a reinforcing agent to enhance strength. Every year almost over a billion tyres are manufactured throughout the entire world, thus making the industry one of the leading customers of vulcanised rubber.

Here is a list of some other vulcanised rubber uses:

Conveyor belts

Vibration dampers

Rubber hoses

Erasers

Insulation

Toys

Shock absorbers

Shoe soles

Rubber-lined tanks

Conclusion

To conclude, it can be said that vulcanisation is how elastomers are cured. It deals with treating raw rubber using sulphur or other curatives, like peroxide and metal oxides, and creating a cross-link between polymer chain segments. This is done to develop a rubberised material possessing outstanding rigidity and durability, which is why vulcanised rubber was invented by Charles Goodyear. Vulcanised rubber is used in almost all sorts of industries around the globe.